Image Source: AI Generated

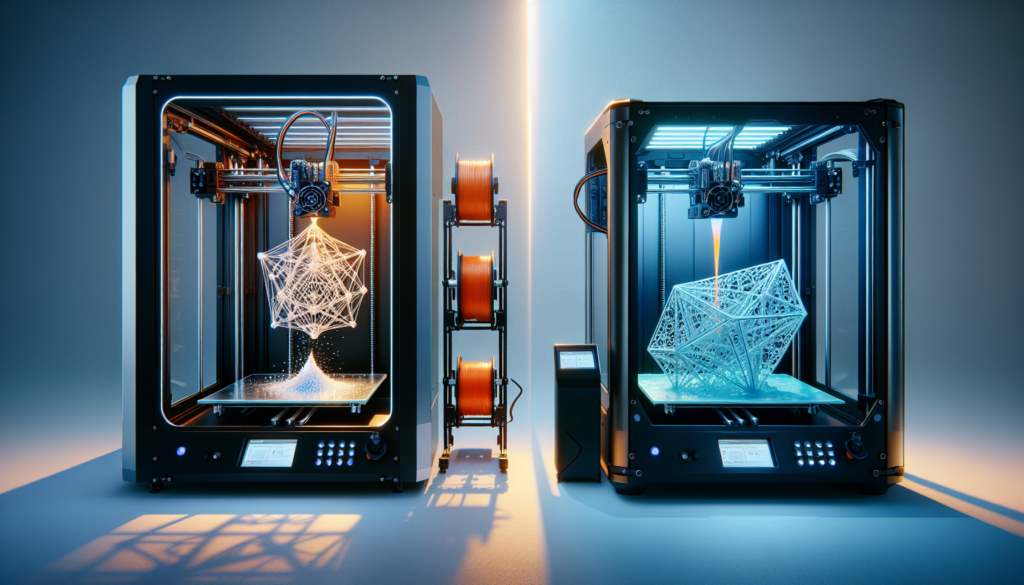

In the world of 3D printing, we’re often faced with a crucial decision: resin 3D printer vs filament. This choice has a significant impact on our projects, influencing everything from print quality to material strength. As enthusiasts and professionals alike, we find ourselves navigating the complexities of these two technologies, each with its own set of advantages and challenges.

We’ll dive into the key aspects that set these printing methods apart. Our exploration will cover print quality and resolution, giving us insights into the level of detail each can achieve. We’ll also look at cost considerations and efficiency to understand the financial implications. Finally, we’ll examine ease of use and post-processing requirements, which are crucial factors in our day-to-day printing experience. By the end, we’ll have a clearer picture of how resin and filament 3D printers stack up against each other.

When thinking about whether resin or filament 3D printers are the right choice, it’s always wise to look for advice. Here are our thoughts on the Top Filament Printers of 2024.

Print Quality and Resolution

When comparing resin 3D printers vs filament, print quality and resolution are key factors to consider. Let’s dive into the details of both technologies to understand their strengths and limitations.

Resin Print Quality

Resin 3D printing excels in producing highly detailed and smooth prints. This technology uses liquid photopolymer resin that’s cured layer by layer using UV light. The result is prints with almost invisible layer lines, giving a polished look right off the printer . Resin printers typically offer outstanding resolution, with layer heights as small as 25-50 microns . This level of detail makes resin printing ideal for creating intricate models, figurines, and miniatures.

One of the main advantages of resin printing is its ability to capture fine details and produce smooth surfaces. The liquid nature of the resin allows for precise curing, resulting in sharper edges and more accurate reproduction of small features. This makes resin printing particularly suitable for applications that require high precision, such as jewelry making or dental models.

Filament Print Quality

Filament 3D printing, also known as Fused Deposition Modeling (FDM), uses thermoplastic filaments to build objects layer by layer. While filament printers have improved significantly over the years, they generally can’t match the resolution and surface smoothness of resin printers.

Filament prints often feature visible layer lines, which can affect the overall smoothness of the surface . The resolution is typically limited by the nozzle size, which is commonly around 0.4 mm . However, using smaller nozzles can improve detail, although it also increases print time.

Comparing Resolution

When it comes to resolution, resin printers have a clear advantage. They can achieve layer heights as low as 10-25 microns, resulting in incredibly smooth surfaces . In contrast, filament printers typically have layer heights ranging from 50 to 400 microns, with 200 microns being a common setting for balancing quality and print speed.

Cost Considerations and Efficiency

When comparing resin 3D printers vs filament, cost and efficiency are crucial factors to consider. Let’s break down the expenses and efficiency aspects of both technologies.

Resin Cost

Resin for 3D printing typically costs more than filament. Standard resins range from USD 99.00 to USD 200.00 per liter. However, the price can vary depending on the quality and type of resin. Budget-friendly options are available for around USD 20.00 to USD 35.00 per kilogram, while engineering resins start at USD 40.00 per kilogram.

It’s important to note that resin printing requires additional equipment, such as a curing station and cleaning supplies. These extras can add USD 50.00 to USD 200.00 to your initial setup costs . Moreover, resin tanks need regular replacement, which can cost around USD 40.00 each.

The resin printers themselves are on average pricier than their filament counterparts, typically sitting around USD 500.00 and the higher end models that have a higher resin holding capacity can go from USD1000.00 up to USD 2000.00. Elegoo and AnyCubic have some really nice printers to take a look at.

Filament Cost

Filament is generally more affordable than resin. Standard filaments like PLA and ABS typically cost between USD 15.00 and USD 30.00 per kilogram . Engineering filaments, such as PC, Nylon, and ASA, range from USD 50.00 to USD 100.00 per kilogram.

The lower cost of filament materials makes it an attractive option for those looking to minimize expenses in 3D printing. Additionally, filament printers require less maintenance and fewer accessories, further reducing overall costs.

This is one area where there are some big differences between filament and resin printing. Cost of materials, tools, and time are starkly incomparable between the two printing types. Filament printers shine in this regard because of their ease of entry for beginners, printing is mostly plug and play, and there’s hardly any work that goes into a finished product once the printer is done with it. However, as was mentioned before, quality is traded off, if that plays a factor in the decision making. Considering everything mentioned, these printers find themselves on the more affordable range than resin, often being around USD 300.00 to USD 600.00 and the higher end printers with enclosures and large build volumes can run up to USD 2000.00. Prusa, Bambu, Ankermake, and Anycubic are just some of the household names in the business and have some good and reliable printers to back that up.

Efficiency Comparison

When it comes to efficiency, both resin and filament printers have their strengths. Resin printers excel in producing highly detailed prints with smooth surfaces, making them ideal for intricate models and prototypes. However, they often have smaller build volumes and require more post-processing time.

Filament printers, on the other hand, can handle larger print volumes and are generally faster for bigger objects. They also tend to be more user-friendly and require less post-processing. However, they may not achieve the same level of detail as resin printers.

In terms of material efficiency, resin printing can be more wasteful due to the need for supports and the potential for unused resin. Filament printing allows for easier recycling of scraps and generally produces less waste.

Ease of Use and Post-Processing

When comparing resin 3D printers vs filament, ease of use and post-processing requirements are crucial factors to consider. Let’s dive into the details of both technologies to understand their workflows and challenges.

Resin Printing Process

The resin 3D printing process starts with pouring the resin into the printer’s vat. It’s important to shake the resin vigorously before pouring to ensure proper mixing of components. Once the print is complete, the model needs to be carefully removed from the build plate using a metal spatula.

Filament Printing Process

The filament 3D printing process is generally more straightforward than resin printing. You simply load the filament spool, and the printer melts and extrudes the material through a nozzle. Once the print is done, you can usually remove the model from the build plate with minimal effort.

Post-Processing Requirements

Resin prints require more extensive post-processing compared to filament prints. After printing, resin models need to be washed in a solvent like isopropyl alcohol (IPA) or a specialized cleaning solution to remove excess resin. This cleaning process typically takes about 10 minutes and may involve using an ultrasonic cleaner or manual agitation.

After cleaning, resin prints need to be post-cured under UV light to achieve their final material properties. This step is crucial for ensuring optimal strength and durability. Post-curing can be done using sunlight, UV lamps, or dedicated curing stations.

Filament prints, on the other hand, generally require minimal post-processing. In most cases, you might only need to remove support structures and perhaps do some light sanding to smooth out layer lines. Unlike resin prints, filament prints don’t need washing or post-curing.

In terms of safety, resin printing requires more precautions. You’ll need to wear gloves, safety glasses, and work in a well-ventilated area due to the potential hazards of liquid resin. Filament printing is generally safer and doesn’t require as much protective equipment.

Conclusion

The choice between resin and filament 3D printers has a big impact on the outcome of printing projects. Each technology brings its own strengths to the table, from the high-detail capabilities of resin printers to the versatility and cost-effectiveness of filament printers. The decision ultimately comes down to the specific needs of the project, balancing factors like print quality, cost, and ease of use.

For those looking to create intricate models with smooth surfaces, resin printing might be the way to go. On the flip side, if you’re after larger prints or need a more budget-friendly option, filament printing could be your best bet. Whichever path you choose, both technologies continue to push the boundaries of what’s possible in 3D printing, opening up new possibilities for creators and innovators alike.

FAQs

What are some drawbacks of using resin in 3D printing?

Resin 3D printing presents several challenges, such as the confined print size, which is generally smaller compared to filament printers. The process is also time-consuming as it involves extensive cleaning, curing, and sanding of the supports on the print. Additionally, resin printing can be quite messy.

Do resin prints offer better quality than prints made with PLA filament?

Resin 3D prints generally provide superior intricacy and detail compared to PLA filament prints. They are also notably more robust. On the other hand, while PLA filament does possess some tensile strength, it is more prone to shattering or breaking.

For printing miniatures, should I choose resin or filament?

Resin is usually the preferred choice for miniatures because of its ability to achieve exceptional detail and a smoother surface finish. Resin printers, such as SLA or DLP, are particularly adept at capturing intricate features. However, filament printers, like those using PLA, can also yield satisfactory results for larger miniatures and are more beginner-friendly and cost-effective.

Is it easier to operate a resin printer compared to other types of 3D printers?

Resin 3D printers are relatively straightforward to use, especially when compared to FDM printers. They are easy to set up and typically do not require assembly.

This post was crafted with the support of AI to provide you with the most accurate, high-quality, and up-to-date content.