Introduction

High-speed 3D printing is rapidly reshaping the manufacturing landscape, offering faster production times, improved efficiency, and better print quality. One of the key innovations driving this revolution is Klipper firmware—an advanced open-source firmware that optimizes printer performance by offloading complex calculations to an external processor. By integrating Klipper, manufacturers and hobbyists alike can achieve unprecedented print speeds without sacrificing precision.

In this guide, we’ll explore how Klipper firmware enhances high-speed 3D printing, its advantages over traditional firmware, how to set it up, and which printers are best suited for Klipper in 2024.

What is Klipper Firmware and How Does It Enable High-Speed 3D Printing?

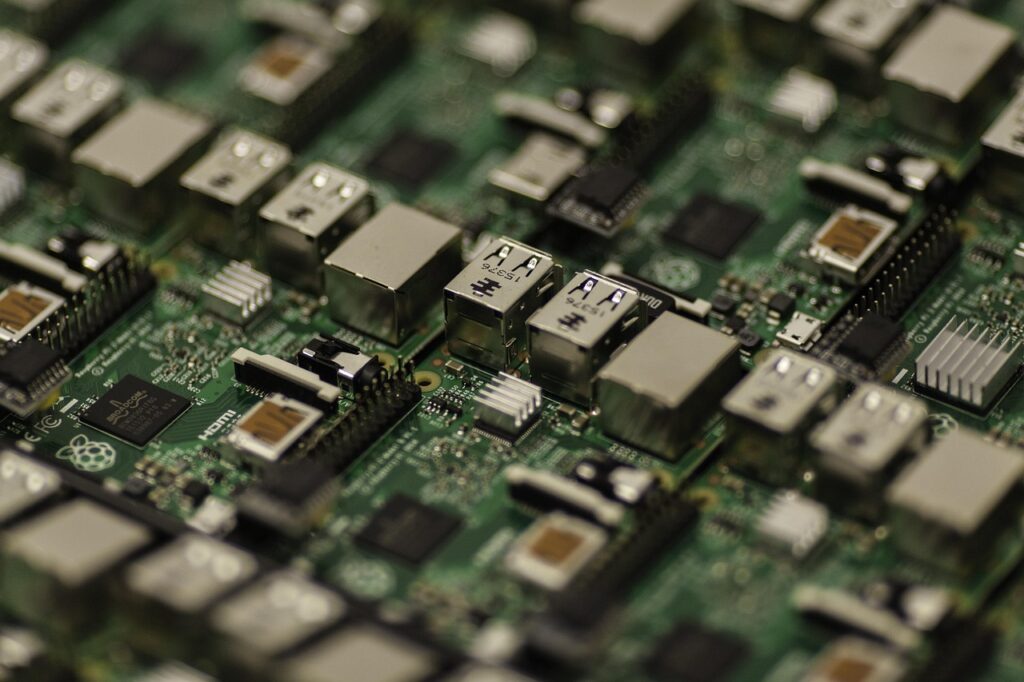

Klipper firmware is an advanced motion control system designed to improve the performance of FDM (Fused Deposition Modeling) 3D printers. Unlike traditional firmware like Marlin, Klipper delegates complex calculations to a more powerful external processor (such as a Raspberry Pi) instead of relying solely on the printer’s mainboard.

Key Features That Boost Print Speed:

- Faster Motion Planning: Klipper allows higher acceleration and jerk limits, significantly reducing print times.

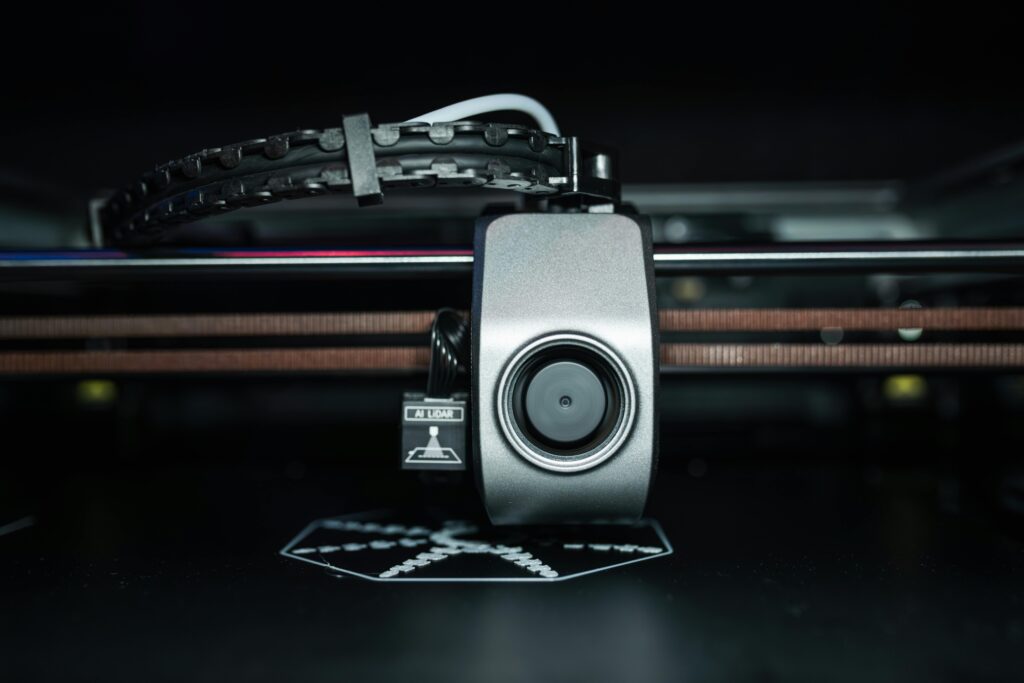

- Input Shaping Technology: Compensates for vibrations and mechanical resonance, leading to smoother, high-speed prints.

- Multiple Stepper Control: Uses advanced algorithms to optimize stepper motor movements, increasing precision at high speeds.

- Pressure Advance: Improves extrusion consistency, reducing stringing and blobs even at rapid print speeds.

By utilizing Klipper firmware, users can print up to 3–5 times faster than with traditional firmware while maintaining excellent print quality.

Why High-Speed 3D Printing is Changing the Industry

1. Faster Prototyping and Production

Industries such as automotive, aerospace, and medical device manufacturing require rapid prototyping. High-speed 3D printing enables companies to iterate designs quickly, reducing time-to-market for new products.

2. Cost Reduction in Manufacturing

By increasing print speeds, manufacturers can produce parts more efficiently, reducing labor and operational costs. Faster prints mean more output in less time, leading to increased profitability.

3. Higher Precision at Faster Speeds

With traditional firmware, printing at high speeds often results in poor accuracy, ringing, and layer shifts. Klipper’s advanced motion planning and input shaping technology mitigate these issues, ensuring high precision even at elevated speeds.

4. Enabling Large-Scale Batch Production

Klipper’s ability to control multiple 3D printers simultaneously makes it an excellent choice for farms and mass production setups, where batch printing is required for commercial applications.

How to Set Up Klipper for High-Speed 3D Printing

Installing Klipper firmware requires a compatible 3D printer, a Raspberry Pi (or similar SBC), and some technical setup. Here’s a step-by-step overview:

Step 1: Check Printer Compatibility

Klipper supports a variety of FDM printers, including models from Creality, Anycubic, and Prusa. Check the official Klipper documentation for your printer’s compatibility.

Step 2: Install Klipper on a Raspberry Pi

- Download and install Fluidd or Mainsail, web interfaces that help control Klipper.

- Flash the Klipper firmware onto your 3D printer’s mainboard using a USB connection.

- Connect the Raspberry Pi to your printer and configure it via SSH.

Step 3: Configure Input Shaping and Pressure Advance

- Run input shaping tests to reduce vibrations at high speeds.

- Tune pressure advance settings to optimize extrusion.

Step 4: Start Printing and Fine-Tune Settings

Once installed, gradually increase your print speeds while monitoring print quality. Test prints can help identify optimal acceleration and jerk settings.

Furthermore, here are some great instructional youtube videos that go through the Klipper installation step by step:

- Install Klipper on ANY 3d printer – Part 1 – Intro and the Basics

- How To Get Started With Klipper On Your 3D Printer – Full Process Explained Quickly!

Best 3D Printers for High-Speed Printing with Klipper in 2024

Not all printers can handle high-speed printing efficiently. Below are some of the best models for Klipper-enhanced 3D printing in 2024.

| Printer Model | Max Speed (mm/s) | Key Features | Price Range |

|---|---|---|---|

| Bambu Lab X1 Carbon | 500mm/s | AI-assisted leveling, CoreXY, input shaping | $1,199 |

| Voron 2.4 | 350mm/s | Fully customizable, CoreXY motion system | $1,000+ (DIY Kit) |

| Creality K1 | 600mm/s | Built-in Klipper, high-speed CoreXY design | $599 |

| Anycubic Kobra 2 Pro | 500mm/s | Auto-bed leveling, direct drive extruder | $399 |

Each of these printers either comes with Klipper pre-installed or is highly compatible with it, making them great choices for high-speed printing.

Frequently Asked Questions (FAQs)

1. Is Klipper only for advanced users?

While Klipper requires some technical setup, it has become increasingly accessible with user-friendly interfaces like Fluidd and Mainsail, making it suitable for intermediate users.

2. Can I install Klipper on any 3D printer?

Klipper is compatible with most FDM 3D printers that support firmware flashing, but some models may require additional hardware, like a Raspberry Pi.

3. Does high-speed 3D printing affect print quality?

Not necessarily. With proper tuning, high-speed 3D printing can maintain excellent detail while reducing print times dramatically.

4. What are the main downsides of Klipper?

- Requires additional hardware (e.g., Raspberry Pi).

- Initial setup can be complex for beginners.

- Not all 3D printers are compatible without modification.

Related Articles

- Top Filament Printers of 2024 Unveiled

- Essential Guide: 3D Printing Tools and Accessories for Your Setup!

- Best 3D Printer Tool Kits for Beginners and Pros

Other Great Resources

- The 6 Best 3D Printers with Klipper Firmware – CleverCreations

- Klipper Firmware: What is it & How to Use – PrintingAtoms

- Klipper Firmware: 6 Key Reasons to Use It for Your 3D Printer – CleverCreations

Conclusion

High-speed 3D printing with Klipper firmware is revolutionizing manufacturing, offering faster, more efficient, and highly precise prints. Whether you’re a hobbyist looking to speed up your prints or a manufacturer aiming for mass production, Klipper provides cutting-edge performance improvements that traditional firmware can’t match.

If you’re ready to embrace the future of 3D printing, consider upgrading your printer with Klipper firmware today!