Introduction

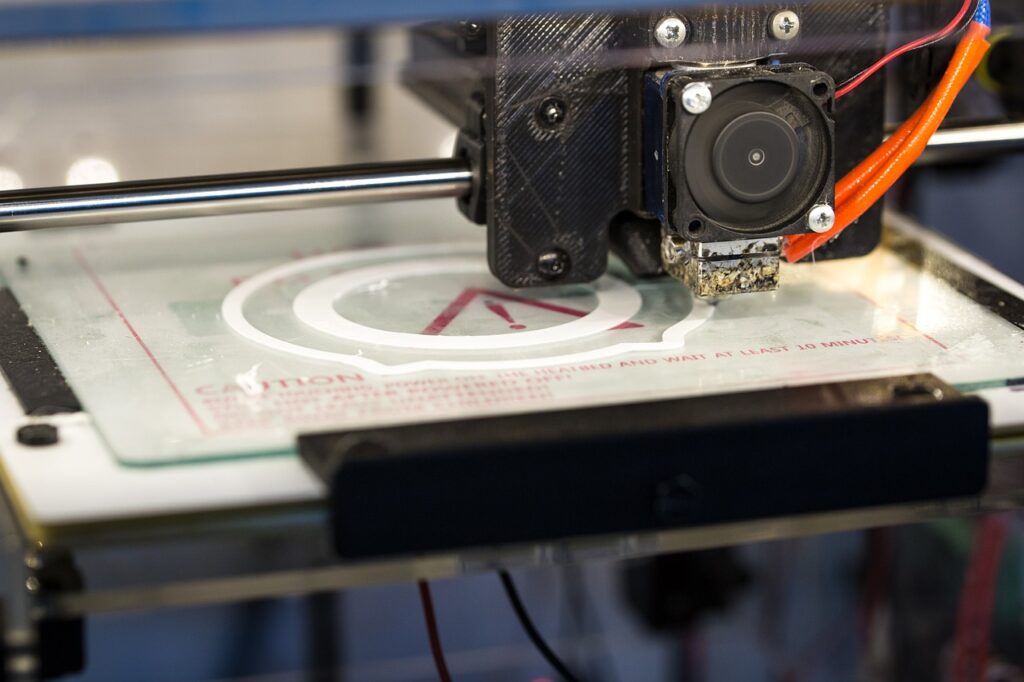

Choosing the right nozzle size for your 3D printer is critical for achieving your desired print results. Nozzle size directly affects print resolution, speed, and strength, making it essential to understand which size fits your project’s requirements. In this guide, we’ll explore the role of nozzle sizes in 3D printing, how to select the right size for different tasks, and examples of commercially available nozzles for various use cases.

How 3D Printer Nozzle Sizes Affect Print Quality

The nozzle size determines the thickness of the extruded filament, influencing the print’s detail, speed, and structural integrity. Here’s a breakdown:

- Fine Details: Smaller nozzle sizes, like 0.2 mm, produce detailed prints but take longer.

- Speed: Larger nozzle sizes, such as 0.8 mm, extrude more filament per layer, resulting in faster prints.

- Strength: Thicker layers from larger nozzles enhance the durability of the printed model.

Example Scenarios:

- 0.2 mm nozzle: Best for creating detailed figurines like miniatures or intricate jewelry designs.

- 0.6 mm nozzle: Ideal for architectural models requiring moderate detail with quicker build times.

- 1.0 mm nozzle: Perfect for large prototypes, such as furniture parts or automotive components.

Commercial Examples:

- This great starter set of nozzles offers a variety of outlet sizes to experiment and find what works best for your setup and style. Featuring 0.2mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm nozzle outlet sizes with DIY Tools and A Ten-Grid Parts Box.

Small Nozzles (0.1–0.3 mm)

Small nozzles are ideal for achieving intricate details and high-resolution prints. They’re commonly used for small-scale models, prototypes, and artistic designs.

Applications:

- Jewelry or art pieces with intricate patterns.

- Parts requiring precision, like mechanical connectors.

Advantages:

- High resolution and surface smoothness.

- Excellent for printing small features.

Challenges:

- Slower print speeds due to finer layer heights.

- Higher risk of clogging with low-quality or composite filaments.

Standard Nozzles (0.4 mm)

The 0.4 mm nozzle is the go-to size for most 3D printers due to its versatility. It offers a good balance between print quality and speed, making it suitable for a wide range of applications.

Applications:

- Prototypes and functional parts.

- Everyday prints like phone stands or toys.

Advantages:

- Balanced resolution and speed.

- Easy to use and widely available.

Challenges:

- Limited detail for highly intricate models.

Large Nozzles (0.6–1.2 mm)

Large nozzles are designed for fast, robust prints where fine details are less critical. They’re perfect for creating durable parts or scaling up production.

Applications:

- Rapid prototyping of large objects.

- Printing functional parts requiring high strength, such as brackets or enclosures.

Advantages:

- Significantly faster print times.

- Stronger layer adhesion due to thicker extrusion.

Challenges:

- Reduced surface smoothness.

- Limited suitability for intricate designs.

Material Considerations for Nozzle Sizes

Selecting the right nozzle material ensures consistent print quality and longevity. Here’s an overview:

Brass Nozzles:

- Best For: PLA, ABS, and other non-abrasive filaments.

- Example Upgrade: Creality MK8 Brass Nozzle Set

Hardened Steel Nozzles:

- Best For: Abrasive filaments like carbon fiber or glow-in-the-dark materials.

- Example Upgrade: Micro Swiss 0.4 mm Hardened Steel Nozzle

Ruby-Tipped Nozzles:

- Best For: Printing with highly abrasive filaments while maintaining precision.

- Example Upgrade: Olsson Ruby Nozzle

Tips for Choosing the Right Nozzle Size

- Consider the Project’s Complexity: Use smaller nozzles for intricate parts and larger nozzles for big, simple shapes.

- Match Nozzle Material to Filament Type: Use hardened nozzles for abrasive filaments and brass nozzles for standard materials.

- Think About Speed vs. Detail: Prioritize speed for prototypes and detail for final products.

FAQs About 3D Printer Nozzles

Q: How often should I replace my nozzle?

Nozzles should be replaced every 3–6 months, or sooner if using abrasive filaments frequently.

Q: Can I switch nozzle sizes on my printer?

Most 3D printers allow nozzle changes, but ensure compatibility with your printer model and hotend.

Q: What’s the best way to clean a nozzle?

Use a nozzle cleaning needle and gently heat the nozzle to remove debris or filament buildup.

Related Articles

- Best 3D Printer Tool Kits for Beginners and Pros

- 3D Printing Hardware Upgrades You Need for Your Setup!

- Essential Guide: 3D Printing Tools and Accessories for Your Setup!

Great Additional Articles

- 3D Printer Nozzle Guide: Sizes, Materials, and Types

- What’s the Best 3D Printer Nozzle Size to Use?

- Mastering the Nozzle Size: A Comprehensive Guide to Optimizing Your 3D Printer

Conclusion

The choice of nozzle size can make or break your 3D printing project. From high-resolution designs to rapid prototyping, understanding nozzle sizes and materials will help you achieve your desired results. Explore your printer’s potential by experimenting with different nozzle sizes and upgrading to premium materials when needed.