Introduction

3D printing hardware upgrades that can transform your printer into a high-performing machine, offering makers, hobbyists, and professionals the opportunity to create precise models, prototypes, and functional parts from home or office setups. Most entry-level printers come with standard components that limit their performance, reliability, and the types of materials they can handle. With the right hardware upgrades, you can take your 3D printer to the next level, enhancing print quality, broadening material compatibility, and even speeding up print times.

Upgraded Extruder Assembly

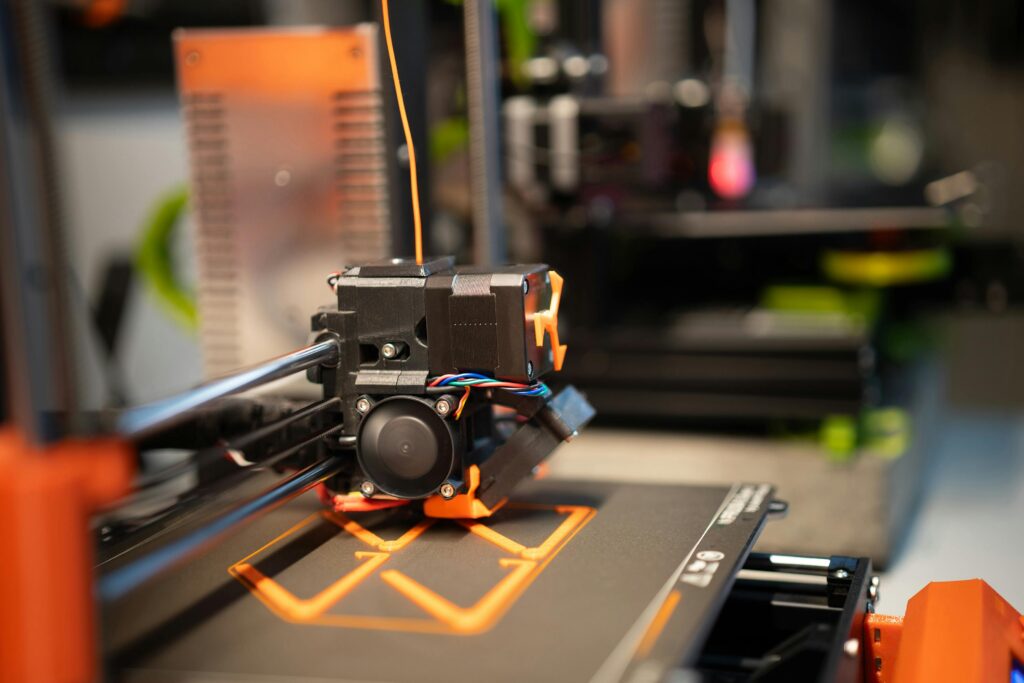

An upgraded extruder is one of the first and most impactful changes you can make to your 3D printer. The extruder is responsible for feeding filament through the hotend, so any issues here—such as filament slipping, inconsistent feeding, or clogs—will affect print quality. Many entry-level printers use simple Bowden extruders, but high-quality options are available for all types of 3D printers.

Direct Drive Extruders

Direct drive extruders have the filament drive mechanism mounted close to the hotend, resulting in more precise filament control, especially for flexible materials like TPU and TPE. This setup provides better retraction control and can reduce filament grinding and skipping.

Examples of Direct Drive Extruders:

- E3D Hemera: Known for its reliability, the E3D Hemera offers direct extrusion and dual-drive gears for consistent filament flow. It’s compatible with a wide range of materials, including flexibles.

- Bondtech LGX: This extruder uses dual drive gears, delivering powerful and precise filament feeding. The LGX is known for its durability and is compatible with direct drive and Bowden setups.

Benefits:

- Improved retraction control, which reduces stringing and blobbing.

- Excellent for flexible filaments, which often cause issues with Bowden extruders.

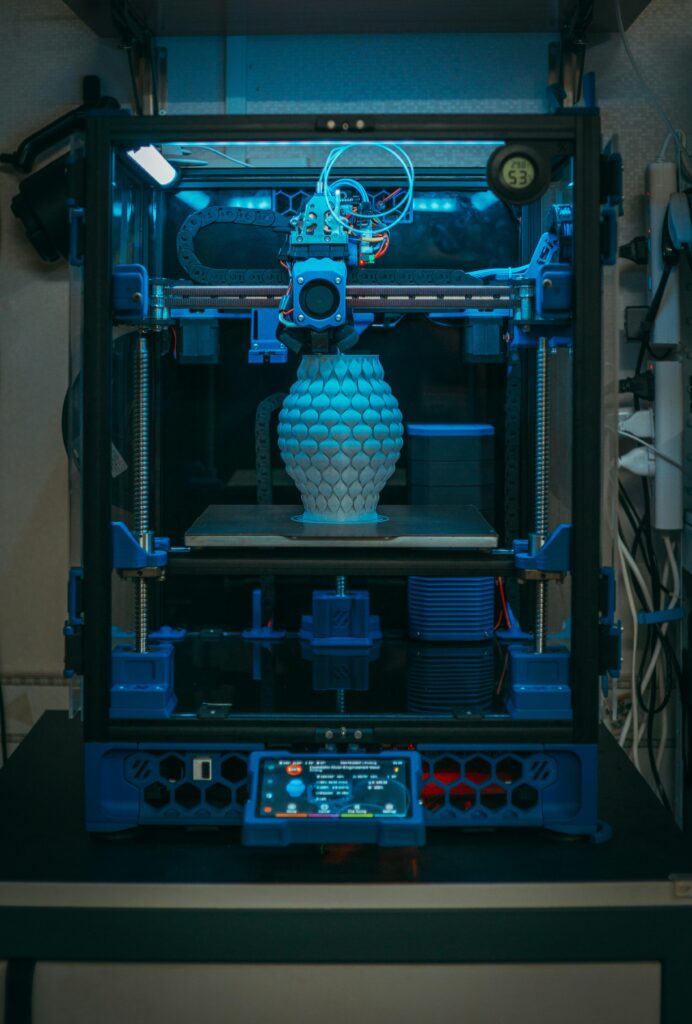

Dual Extruder Systems

For advanced users, dual extruder systems open the door to multi-material and multi-color printing. This 3D printing hardware upgrade allows you to print with a primary material and a secondary dissolvable support material, enabling the production of complex structures with intricate details.

Examples of Dual Extruder Systems:

- Prusa Multi-Material Upgrade 2S: This add-on for the Prusa i3 MK3 enables multi-material printing with up to five colors or materials, offering great flexibility and a user-friendly setup. Prusa having incredibly versatile machines, we have included the i3 MK3S+ in our list of top filament printers for 2024, check out our post to see other printers that match up!

- FlashForge Creator Pro Dual Extruder: This printer comes pre-configured with dual extruders, allowing easy switching between two different filament types or colors.

Benefits:

- Allows multi-material printing, such as combining a structural filament with a dissolvable support filament.

- Great for creating complex or color-separated prints without additional post-processing.

All3DP Guide to Extruders of All Kinds – A deep dive into the various types of extruders and their uses.

Enhanced Bed Leveling Solutions

Bed leveling is essential for ensuring that the first layer adheres properly to the build surface, which is crucial for the success of the entire print. Many entry-level printers come with manual leveling, which requires periodic adjustments. Upgrading your 3D printing hardware to an automatic bed leveling (ABL) system can save time and improve print quality.

Manual Bed Leveling Tools

For users who prefer manual bed leveling, using precise tools like feeler gauges or digital indicators can make the process easier and more consistent.

Take a look at our guide on essential tools and accessories that we know will take your 3D printing setup to the next level.

Examples of Manual Bed Leveling Upgrades:

- Feeler Gauges: These affordable, precise tools allow you to check the distance between the nozzle and bed for consistent leveling.

- Precision Leveling Knobs: Larger, easily adjustable knobs make manual bed leveling less time-consuming and more accurate.

Benefits:

- Cost-effective and simple for those who don’t mind adjusting the bed manually.

- Precise control over bed leveling for consistent first layers.

Automatic Bed Leveling (ABL) Sensors

An ABL sensor, such as the popular BLTouch, uses a probe to detect the bed’s height at multiple points. The printer automatically adjusts for any height variations, eliminating the need for manual leveling and improving the consistency of the first layer.

Examples of ABL Systems:

- BLTouch: A highly compatible ABL sensor that works with many 3D printers. It’s known for its accuracy and reliability.

- EZABL: This capacitive sensor is another option for automatic leveling. It works well with glass and other non-metallic build surfaces.

Benefits:

- Saves time by eliminating the need for manual adjustments.

- Reduces print failures due to poor first-layer adhesion.

Precision Stepper Motors

Stepper motors control the movement of the print head and the bed. Higher-quality stepper motors can significantly reduce vibration and noise while enhancing print precision, especially for fine details. Many stock stepper motors can be upgraded to quieter, more efficient options.

Silent Stepper Motors

Silent stepper motors are engineered to reduce the noise that is common with many 3D printers. This 3D printing hardware upgrade is particularly useful in home or office settings where noise levels matter.

Examples of Silent Stepper Motors:

- Trinamic TMC2208 Drivers: Known for their near-silent operation, these drivers are popular upgrades for quiet 3D printing.

- TMC2130 Drivers: These provide quiet and smooth motion control, as well as additional control features for advanced users.

Benefits:

- Reduced noise makes the printer suitable for residential spaces.

- Smoother motion improves the surface finish of prints.

High-Precision Stepper Motors

For users focused on achieving detailed prints, high-precision stepper motors can reduce layer inconsistencies and enhance print quality.

Examples of High-Precision Motors:

- LDO Precision Stepper Motors: Known for high torque and low noise, these motors are used in various high-end 3D printer models.

- Moons’ Stepper Motors: These are premium-quality stepper motors that provide precise control, making them ideal for intricate or high-resolution prints.

Benefits:

- Enhanced layer resolution for detailed or complex prints.

- Minimizes risks of print issues like layer shifting.

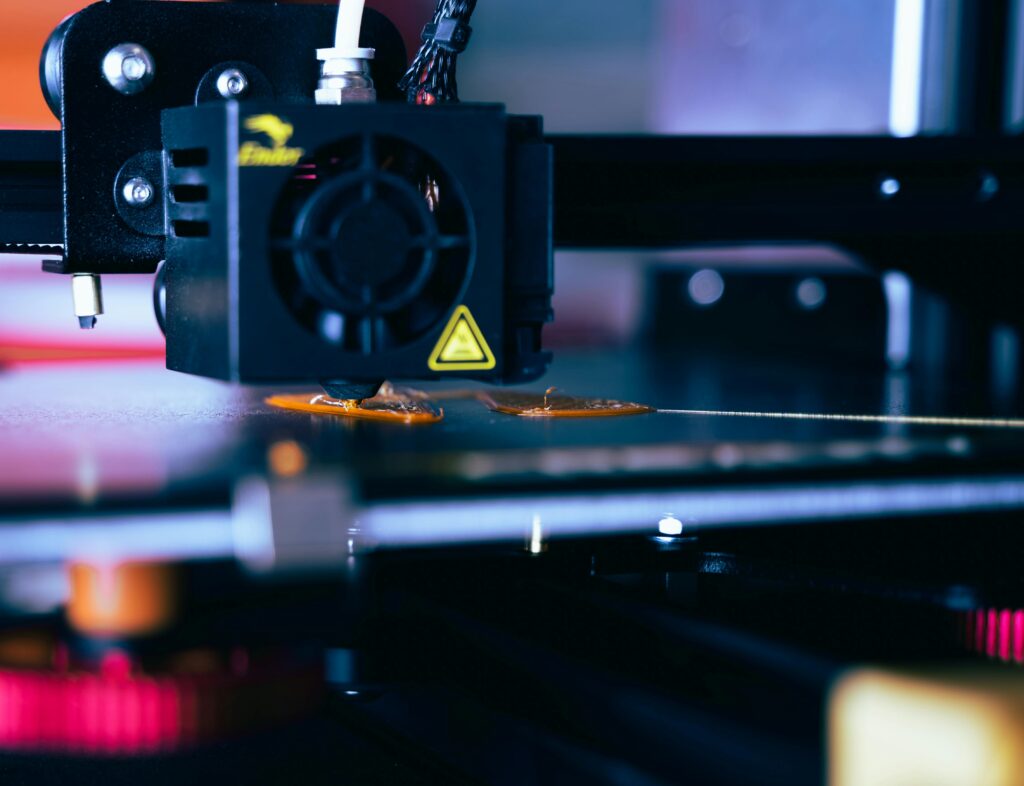

Advanced Hotends and Nozzles

The hotend and nozzle are crucial components that determine the materials and temperatures your printer can handle. Standard hotends and nozzles are suitable for basic materials like PLA, but upgrading can open the door to high-temperature and abrasive materials.

All-Metal Hotends

All-metal hotends, unlike PTFE-lined hotends, can handle much higher temperatures, which is ideal for advanced filaments like polycarbonate and nylon.

Examples of All-Metal Hotends:

- E3D V6: A highly versatile all-metal hotend that supports a range of filaments and is widely compatible with different 3D printers.

- Micro Swiss All-Metal Hotend: This upgrade is popular for Creality printers and supports high-temperature printing with minimal risk of clogging.

Benefits:

- Enables high-temperature printing for advanced filaments.

- Longer lifespan and reduced clogging compared to standard hotends.

Hardened Steel Nozzles

Standard brass nozzles wear out quickly when using abrasive filaments like carbon fiber composites. Hardened steel nozzles are much more durable, maintaining performance with even the most challenging materials.

Examples of Hardened Steel Nozzles:

- Nozzle X by E3D: Designed to handle highly abrasive filaments, the Nozzle X is a premium option for users printing with fiber-filled materials.

- Micro Swiss Hardened Steel Nozzle: Compatible with many printer models, this nozzle resists wear from abrasive filaments and provides consistent extrusion.

Benefits:

- Resists wear from abrasive filaments, extending nozzle lifespan.

- Reduces the need for frequent nozzle replacements.

3Dpros 3D Printer Hotend Guide– An in-depth look at different hotends and their benefits.

Improved Build Surface Options

The build surface affects print adhesion, ease of removal, and the quality of the print’s first layer. While glass beds or basic heated beds work for many materials, specialized surfaces can optimize adhesion and ease of use.

PEI (Polyetherimide) Sheets

PEI sheets provide excellent adhesion for a wide variety of filaments, including PLA, PETG, and ABS. They’re durable and require minimal maintenance beyond regular cleaning.

Examples of PEI Sheets:

- Wham Bam Flexi Plate System: This flexible, magnetic PEI surface offers great adhesion and makes print removal easy.

- BuildTak PEI Sheet: Known for durability and excellent adhesion, especially with ABS and PLA.

Benefits:

- Consistent adhesion, reducing the risk of warping.

- Durable and long-lasting surface.

Magnetic and Flexible Build Plates

Magnetic and flexible build plates make it easier to remove prints by allowing users to flex the surface, popping off the print without scraping.

Examples of Magnetic Build Plates:

- Creality Magnetic Bed: Compatible with multiple Creality models, this flexible bed is affordable and easy to install.

- Energetic Double-Sided PEI Spring Steel Sheet: This flexible plate is popular among makers who print with a range of materials.

Benefits:

- Simplifies print removal, reducing risk of damaging prints.

- Versatile for a variety of filament types.

Conclusion

These 3D printer hardware upgrades can transform your machine’s performance, from enhanced print quality and material compatibility to quieter operation and easier print removal. By choosing the right upgrades—whether it’s a direct drive extruder for flexible filaments, a silent stepper motor for quieter prints, or a PEI sheet for optimal bed adhesion—you’ll create a more efficient, user-friendly, and high-performing setup. Embrace these upgrades to unlock the full potential of your 3D printing journey and elevate your printing experience!

This post was crafted with the support of AI to provide you with the most accurate, high-quality, and up-to-date content.